Top Strategies for Enhancing Performance with LED Connectors

In recent years, the demand for LED connectors has surged as the global LED lighting market has experienced significant growth, projected to reach $105.9 billion by 2027, with a compound annual growth rate (CAGR) of 13.4% from 2020 to 2027, according to a report by Fortune Business Insights. As industries increasingly prioritize energy efficiency and sustainability, the versatility and performance of LED connectors become crucial in optimizing lighting solutions. However, with the complexity of applications, it's imperative for manufacturers and users alike to adopt top strategies to enhance performance and reliability in LED connector systems. In this blog, we will explore essential methods to improve the efficacy of LED connectors, ensuring they meet both industry standards and user expectations while contributing to the overarching goals of the evolving lighting landscape.

Understanding the Basics: What are LED Connectors?

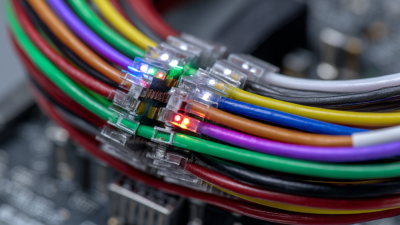

LED connectors play a crucial role in the performance and reliability of LED lighting systems. At their core, these connectors are designed to facilitate the easy and secure connection of LED strips, modules, and other components. Understanding the types of connectors available—such as solderless, soldered, and specialized connectors—can greatly influence the effectiveness of a lighting installation. Each type offers distinct advantages, catering to various applications, from home lighting to large-scale commercial setups.

When selecting LED connectors, it's essential to consider factors such as the environment in which they'll be used, the electrical specifications needed, and the ease of installation. For instance, waterproof connectors are ideal for outdoor lighting projects, while low-profile connectors may be more suited for subtle indoor designs. Additionally, the compatibility of connectors with the LED components chosen can streamline the assembly process and enhance the overall performance of the lighting system. By understanding these basics, users can make informed decisions that lead to improved reliability and aesthetics in their LED lighting setups.

Top Strategies for Enhancing Performance with LED Connectors

Key Types of LED Connectors: Features and Functions

When it comes to optimizing performance through LED connectors, understanding the key types and their applications across different vehicle segments is crucial. In passenger cars, LED connectors are commonly used for interior lighting solutions such as reading lights and backlit controls, enhancing both functionality and aesthetics. The sleek design and energy efficiency of these connectors support the growing demand for innovative lighting systems in modern vehicles.

For light commercial vehicles and heavy-duty trucks, LED connectors play an essential role in exterior lighting. From headlights to tail lights and turn signals, the durability and reliability of LED connectors ensure optimal performance in various weather conditions and operational scenarios. The shift towards LED technology over traditional halogen and Xenon options is driven by the desire for longer-lasting, energy-efficient solutions that offer superior brightness and visibility, ultimately improving safety on the road.

As the global lighting market continues to expand, projected to grow from $154.27 billion in 2024 to $367.88 billion by 2032, the integration of advanced LED technologies in automotive applications is poised to enhance vehicle performance and safety. Understanding the functions and features of different LED connectors will be pivotal for manufacturers aiming to stay competitive in this evolving market landscape.

Performance Optimization: Selecting the Right LED Connectors

Selecting the right LED connectors is crucial for optimizing performance in various lighting applications. According to a report by the LED Connector Association, nearly 30% of LED failures are attributed to poor connector choices, highlighting the importance of selecting connectors that not only fit physical dimensions but also offer electrical reliability. For example, using connectors with low contact resistance can significantly reduce energy loss and enhance overall system efficiency, potentially increasing the lifespan of LED products by up to 50%.

In addition, compatibility with environmental factors is essential for performance optimization. A study from the International Electrotechnical Commission (IEC) indicates that connectors designed for higher temperature ratings can prevent degradation in harsh environments. Choosing connectors with robust materials such as PBT (Polybutylene Terephthalate), which is known for its thermal stability, can improve performance and reliability in challenging conditions, further solidifying the need for diligent selection in LED applications. Ensuring that the chosen connectors meet both electrical and environmental requirements can lead to improved efficiency and a decrease in operational costs.

Installation Best Practices for Enhanced LED Connector Performance

When it comes to optimizing LED connector performance, proper installation practices play a crucial role. One of the foremost considerations is ensuring that connectors are clean and free from contaminants before installation. Dust, dirt, and grease can significantly hinder the electrical connection, leading to inefficient lighting or even complete system failure. Utilizing anti-static wipes and cleaning solutions can help maintain the integrity of the connectors and ensure a robust connection that maximizes performance.

Another important aspect is to establish a secure and proper seating of the connectors. It’s vital to apply the right amount of pressure when connecting to avoid any loose connections that could lead to intermittent performance issues. Additionally, following the manufacturer's guidelines for torque specifications during installation can prevent damage to the connectors and ensure longevity. Regular inspections and maintenance can also identify potential problems early on, allowing for timely intervention to maintain optimal functionality and performance of your LED setup.

Top Strategies for Enhancing Performance with LED Connectors - Installation Best Practices for Enhanced LED Connector Performance

| Strategy | Description | Benefits | Best Practice |

|---|---|---|---|

| Proper Selection of Connectors | Choosing connectors rated for the specific voltage and current requirements. | Ensures safety and longevity of LED installations. | Consult manufacturer specifications before selection. |

| Correct Wiring Techniques | Using the right gauge wire and ensuring proper polarity. | Prevents overheating and ensures efficient energy transfer. | Double-check wiring against circuit diagrams. |

| Regular Maintenance | Scheduled inspections and cleaning of connectors. | Increases reliability and performance of LED fixtures. | Set a maintenance schedule based on usage. |

| Use of Heat Shrink Tubing | Applying heat shrink over connections for protection. | Provides insulation and protects against moisture. | Ensure proper size and heat application for strength. |

| Testing Installations | Conducting electrical tests before finalizing installations. | Identifies issues early, preventing costly repairs. | Use voltage and continuity testers for accuracy. |

Troubleshooting Common Issues with LED Connectors

When dealing with LED connectors, troubleshooting common issues is key to ensuring optimal performance. One frequent problem involves poor connections that may result in intermittent lighting or flickering. It's essential to inspect the connector pins for any signs of damage or corrosion and ensure they are securely attached to the LED strips or panels. Using a multimeter can help verify that there is continuity and that the voltage is within an acceptable range.

Another issue often encountered is overheating, which can lead to damage not just to the connectors but also to the LED components themselves. This scenario may arise from improperly sized connectors or cables that cannot handle the electrical load, leading to melting or even total failure. It’s crucial to choose connectors rated for the power levels needed and to check for any signs of wear regularly. Ensuring that connections are clean and free from dust can also prevent overheating and prolonged life for your LED installations. Identifying and addressing these common problems will help maximize the longevity and performance of LED systems.

Related Posts

-

Exploring Unique Alternatives to Traditional Light Strips for Your Home Decor

-

Unlocking the Technical Specifications of the Best LED Light Wiring Harness for Global Buyers

-

Exploring Unique Alternatives to Traditional LED Wiring Harness Solutions

-

The Ultimate Guide to Choosing the Perfect LED Strip for Your Project

-

How to Choose the Best LED Strip Connector for Your Lighting Projects

-

How to Choose the Best LED Light Harness for Optimal Performance and Efficiency