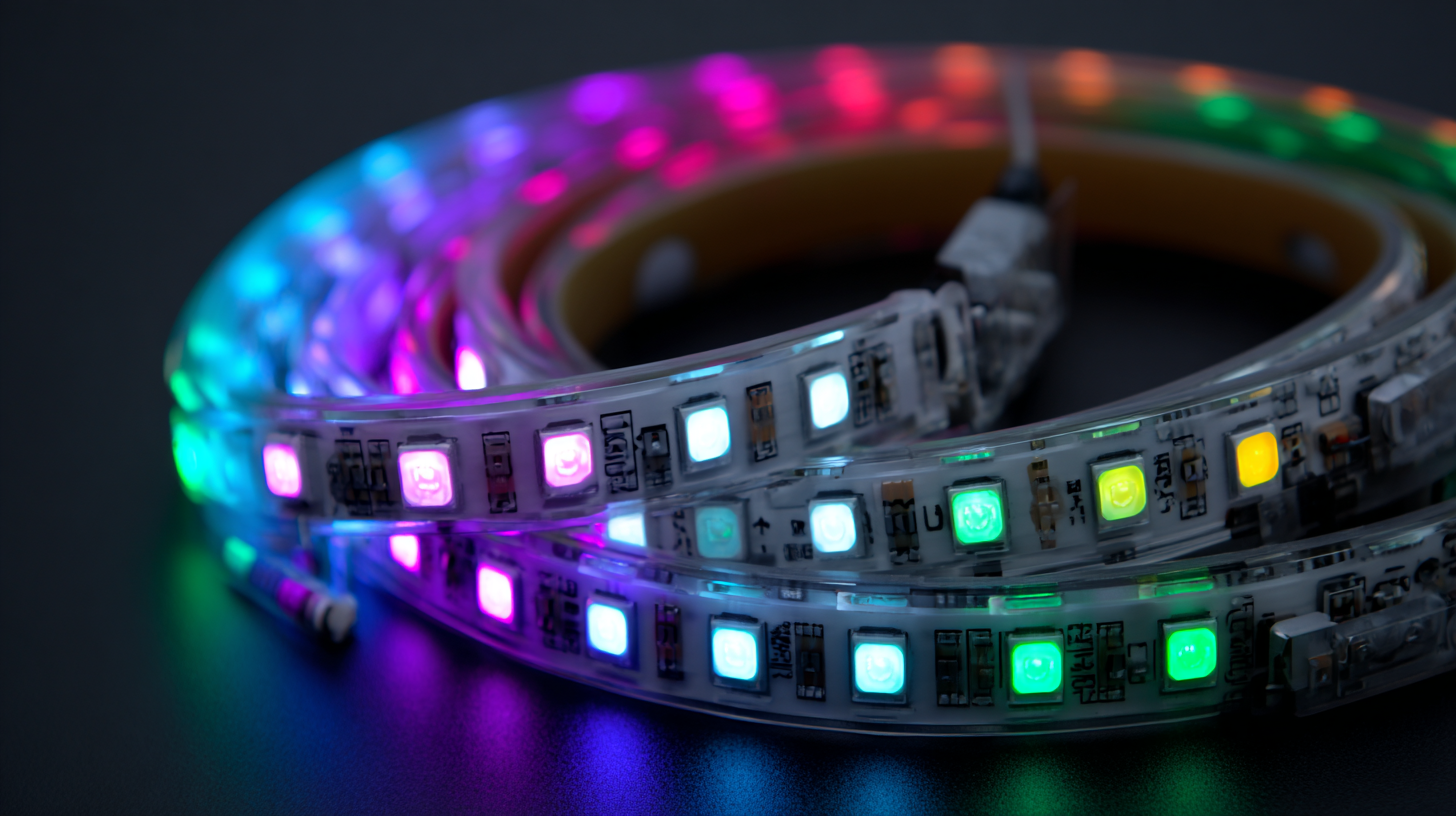

How to Choose the Best LED Strip Connector for Your Lighting Projects

When embarking on a lighting project involving LED strip lights, choosing the right LED strip connector is crucial for ensuring both functionality and aesthetic appeal. With a plethora of options available, understanding the benefits of different types of connectors can significantly enhance your project’s outcome. Whether you are looking for simple plug-and-play solutions or more intricate soldering connectors, the choice you make will impact the durability, flexibility, and ease of installation of your lighting setup. This guide will help you navigate through the various types of LED strip connectors by highlighting their advantages and specific applications, allowing you to select the best option tailored to your unique lighting needs. Emphasizing the importance of selecting the appropriate LED strip connector ensures that your lighting projects shine bright and last long, elevating both ambiance and functionality in your spaces.

Factors to Consider When Selecting LED Strip Connectors

When selecting LED strip connectors for your lighting projects, there are several key factors to consider that can significantly impact both functionality and ease of installation. First and foremost, compatibility is crucial – ensure that the connector matches both the width and type of your LED strip. Popular sizes typically include 10mm or 12mm for the standard SMD 3528 and 5050 strips. Additionally, pay attention to the LED strip’s voltage; common options are 12V and 24V, and a mismatched connector could cause damage to your lighting system.

Another important element is the quality and durability of the connector. Look for connectors made from high-quality materials, such as gold-plated contacts, which can provide better conductivity and resist corrosion. The design of the connector also plays a vital role; some are easier to install, featuring simple push-in designs, while others may require soldering. Lastly, consider any specific requirements for your project, such as connectors that are waterproof for outdoor applications or connectors designed for a seamless continuation of light. Taking these factors into account will help you choose the best LED strip connector for your needs.

Types of LED Strip Connectors and Their Applications

When embarking on lighting projects with LED strips, selecting the right connectors is essential to ensure both functionality and durability. There are several types of LED strip connectors, including solderless connectors, solder-on connectors, and terminal block connectors.

Solderless connectors are popular for their ease of use, allowing quick connections without the need for any tools, making them ideal for DIY projects. According to a recent market analysis by LEDinside, the demand for solderless connectors has grown by 15% annually, reflecting a shift toward user-friendly options in LED lighting applications.

Solderless connectors are popular for their ease of use, allowing quick connections without the need for any tools, making them ideal for DIY projects. According to a recent market analysis by LEDinside, the demand for solderless connectors has grown by 15% annually, reflecting a shift toward user-friendly options in LED lighting applications.

Solder-on connectors, typically preferred by professionals, provide a more secure and permanent solution as they require soldering directly to the LED strips. This type is often used in commercial installations where reliability is crucial. Terminal block connectors offer versatility, allowing for easy disconnection and reconnection, which is particularly useful in temporary setups or for maintenance purposes. The LED connector market is projected to reach $1.5 billion by 2025, driven by advances in LED technology and increasing applications in residential, commercial, and industrial lighting.

Tip: When choosing connectors, consider the environment in which your LED strips will be installed. For outdoor projects, waterproof connectors are essential to withstand the elements. Additionally, always check the compatibility of the connector with your specific LED strip type, as mismatched connectors can lead to performance issues.

Understanding Voltage and Amperage in Connector Selection

When selecting the best LED strip connector for your lighting projects, understanding voltage and amperage is crucial. The voltage of your LED strips should match that of the connector; common options include 12V and 24V. Mismatching these can lead to improper functionality or even damage. Always check the specifications of both the LED strip and the connector to ensure compatibility.

Amperage is another vital factor to consider, as it dictates the amount of current that can safely flow through the connector. If your LED strips draw more current than the connector can handle, it could cause overheating and failure. As a tip, always choose a connector that exceeds the amperage requirements of your LED strip to allow for additional power demands and ensure longevity.

Moreover, utilize connectors that are rated for the total length of your LED strip run. For longer installations, you may need to segment the power supply or use connectors that support higher amperage. Regularly double-check your measurements and calculations to avoid potential hazards. Proper understanding and selection based on voltage and amperage will lead to a successful and safe lighting project.

Tips for Ensuring Secure and Reliable Connections

When choosing LED strip connectors for your lighting projects, ensuring secure and reliable connections is crucial. The first tip is to select connectors that match your LED strip type in terms of size and pin configuration. This helps prevent loose connections that can lead to flickering lights or complete failures. Additionally, opt for connectors with sturdy materials, as plastic components can weaken over time under stress or heat. Look for connectors that provide a snug fit without requiring excessive force, which can damage the strip.

Another important aspect is the method of installation. Solderless connectors offer a convenient option for those who may not have soldering skills. However, for projects requiring maximum durability, consider soldering the connections directly. This method creates a robust bond that withstands movement and environmental changes. Lastly, test the connections before finalizing your installation. By powering on the LED strips and checking each segment of light, you can identify any issues early and make necessary adjustments, ensuring a successful and visually appealing lighting project.

LED Strip Connector Types Usage in Lighting Projects

Troubleshooting Common Issues with LED Strip Connectors

When embarking on LED strip lighting projects, troubleshooting common issues with LED strip connectors can significantly impact the overall success of your installation. One prevalent issue is intermittent connectivity, often caused by poor solder joints or incompatible connector types. According to a report by the Illuminating Engineering Society (IES), around 30% of installation problems stem from connection failures, highlighting the importance of selecting the right connector for your specific LED strips.

Another frequent challenge is voltage drop, which can lead to uneven brightness along the strip. A study published in the Journal of Lighting Research indicates that improper connector usage can exacerbate this issue, resulting in a brightness reduction of up to 20%. To mitigate these problems, choosing connectors that match the width and power requirements of your LED strips is crucial. Using high-quality connectors designed for your specific product can help ensure a reliable, efficient connection and preserve the longevity of your lighting installation.